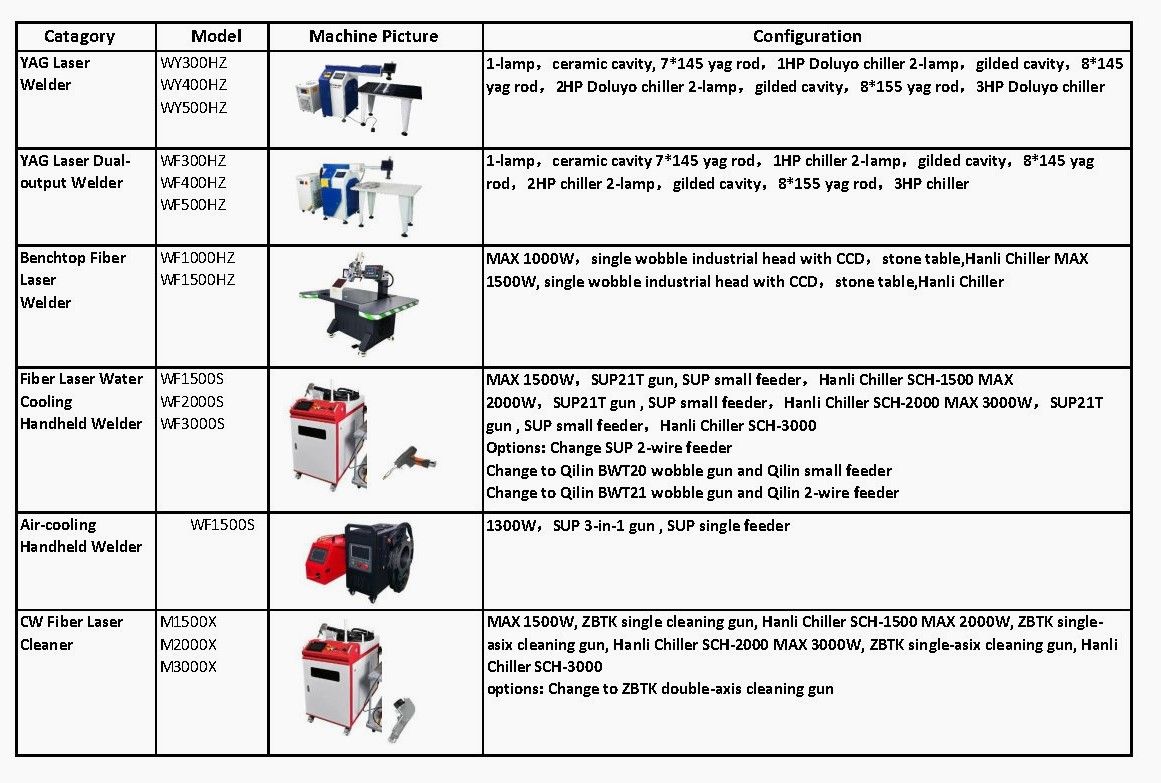

Ascent Fiber and YAG Laser Welders and Cleaners

Fiber Welding, Cleaning, and Cutting:

Fiber laser welding replaced traditional welding methods, TIG and MIG welding.

The laser provides contact-free, high-speed metal welding solutions for advanced manufacturing.

Welding is conducted by melting the metals to create a high-quality weld.

The filler material may be required (as TIG welding).

The laser beam is tightly focused, heat input is minimized, and parts can be handled almost immediately.

- High-precision accuracy for joining small and large parts.

- It does not require skill, dexterity, or lengthy training.

- Minimum distortion due to low heat input.

- Non-contact welding - no degradation in welding quality.

- No current passes through the part.

- Weld dissimilar metals.

- Minimal maintenance

Fiber Welding, Cleaning, and Cutting:

Wobble Welding Head: a mechanism that introduces controlled oscillations or movements during welding. This can enhance the welding quality and efficiency.

SUP Gun

Super laser welding cleaning and cutting three-in-one system hand-held laser welding, laser cleaning, laser cutting integrated system.

The working mode can be freely switched according to different application scenarios, providing diversified solutions for users' different application needs.

QILIN Gun

Double motors handheld wobble welding gun for superior welding

Can move the beam in the following shapes:

The swing graphics can be set to point, line, circle, ellipse, triangle, figure eight, semicircle, and circular filling modes to achieve multi-functional welding.

Accessories:

- Automatic wire feeder single or dual

- Laser safety goggles

- Laser safety welding helmet

- Protective lens

- Nozzle kit

Handheld Laser Welding with Dual Channel Wire Feeder

Including a twin-wire feed system enhances the ability to fill the wire and weld wider seams. Ascent test shows that a single-feed laser welding machine can only handle 1.5mm to 1.8mm seams.

However, with a double-feed laser welding machine, seams as wide as 3-4mm can be successfully welded. Furthermore, this system enables fish-scale welding, ensuring a consistent effect without wire dragging or stuttering. With the convenience of a handheld welding control system, creating fish scale lines becomes effortless, greatly enhancing the overall welding process. The dual wire feeder allows the simultaneous use of two different wire diameters and/or types, eliminating the need to change wire spools and related components. This allows the welding machine to switch between wire sizes or types easily.

OPTION PORTABLE FUME EXTRACTOR:

Let Ascent Experts Assemble All the Pieces of The Equipment Puzzle for your Company

Contact info

Direct line: 416-953-8104

Toll-free: 1-800-927-5107 Extension 1008

Tel: 647-494-7800 Extension 1008

Para asistencia en español marque Ext. 1006.

dov@ascentge.com

Buffalo, New York and Toronto, Ontario

All Rights Reserved | Ascent Equipment (USA) LLC

* Ascent reserves the right to change specifications without notice

All Rights Reserved | Ascent Equipment (Canada) Inc.

Smart Site Design & SEO Services by Green Lotus Agency