The Art of Forming Channel Letters Through Precision Ascent Automation™

Advanced Technology at an Affordable Price

Ascent specializes in CNC and Laser Equipment, and our commitment to quality and innovation sets us apart. Premium Equipment That Won't Break Your Budget All Ascent sign-making equipment includes installation, setup, and training at your facility from Ascent technicians from the USA or Canada. The best warranty in the business two years of materials and labor!

Ascent-4AS Channel Letters

Bending Machine

The ASCENT - 4AS CNC Bending Machine, trusted by leading North American sign manufacturers,

Produces flawlessly channel letters without trim, reverse/halo letters without welding, side-illuminated letters with plastic returns, and more.

Designed to process various materials, including Aluminum (0.040 and 0.063”), Stainless Steel, Galvanized Steel, Nonproprietary Ascent aluminum UL certified Extrusions/ Profiles with competitive pricing, and other materials.

The fourth-generation CNC bending machine ensures precision for side returns.

We assure you of the industry's most straightforward assembly process, with the lowest labor costs and competitive pricing for Ascent UL aluminum extrusions/profiles for side returns.

EDGE-2 Channel Letters Bending Machine:

CNC Bending Machine – The solution for "notching and flanging" trim cap and reverse/halo channel letters.

It can handle aluminum coils up to 0.063”, stainless steel, and galvanized steel.

This full-scale servo system machine delivers accurate results and can perform tight radius bending. The most affordable prices for compatible machines in North America.

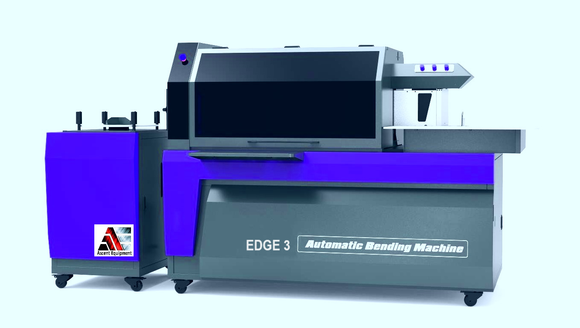

EDGE-3 Channel Letters Bending Machine:

CNC Bending Machine – The solution for "notching and flanging" trim cap and reverse/halo channel letters. It can handle aluminum coils up to 0.063”, stainless steel, and galvanized steel.

This full-scale servo system machine delivers accurate results and can perform tight radius bending. with output cutters, adjustable notches angle, and an additional servo system.

The most affordable prices for compatible machines in North America.

TMB-3 Combination Channel Letters Bending and Trim Machine:

The TMB3 machine is excellent for an entry-level machine and as a trim machine.

- Make the flanging on the channel letter side return from 0.040” aluminum coil.

- Channel letter side return from 0.040” aluminum coil for reverse/halo (ready for welding)

- Processing all plastic trims

- Convert flat aluminum coil to aluminum trim and make the shape of the letter Aluminum trim cheaper than plastic trim; it is durable and does not fade or crack over time

(Industry first)

Channel Letters Stapler

The Ascent Pneumatic Stapler, a pivotal tool in seamlessly fastening the side return to the back of the channel letters with standard commercial galvanized crown staples for “notching and flanging” type letters.

Can be used with ACM or aluminum or polycarbonate.

It has safety features such as a laser pointer.

TM-1 Trim Machine:

Automated high-speed and accurate process ¾”, 1’ and 2” plastic trims.

Equipped with a cutter that can rotate 360 degrees for better accuracy.

Use the same file as your CNC router and bending machine.

Fiber Laser Welders: Handheld Fiber Laser welder

- 1500W, 2000W, and 3000W Water cooling with or without cleaning attachment.

- 1300W air cooling

Featuring an automatic wire feeder (Double or Single Wires)

This equipment is ideal for aluminum, stainless steel, galvanized steel, and brass welding.

This welder is intuitively designed, even for those with minimal training, ensuring quality and efficiency.

This welder can weld aluminum as thin as 0.030”.

The handheld gun can reach up to 10 feet.

FIBER, LASER WELDER TABLETOP (Industry first, for small to medium channel Letters)

Harness precision and power with the Fiber Laser Welder

Table Top.

- A 1500W fiber source,

- Integrated chiller

- CCD camera.

- This equipment seamlessly welds various materials, including aluminum (from 0.030”), stainless steel, galvanized steel,

and brass.

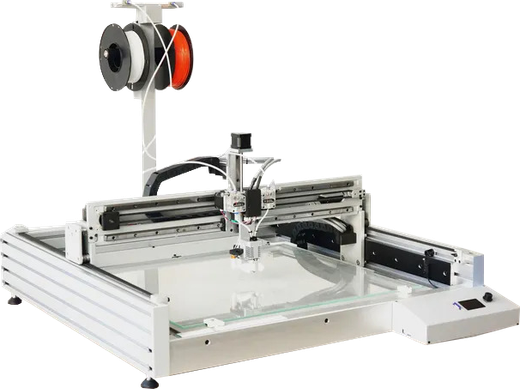

3D Printer

Our cutting-edge 3D Printer is explicitly tailored for channel letters and intricate logos.

With a generous print area of 24” x 24” x 3”

This printer effortlessly brings your designs to life.

Boasting the industry's unparalleled speed, it sets the benchmark for rapid and efficient printing.

What sets this printer apart is its inclusion of unique software that seamlessly transforms 2D designs into 3D shapes.

Embrace the future of additive manufacturing with precision, speed, and innovation.

Laser Cutters Fiber laser cutter

Price/performance breakthroughs include installation by factory technicians and two years warranty.

The fiber laser cutter is 3000W up to 6000W.

5’x10’ for metal cutting

Completely enclosed with a shuttle table for loading and unloading.

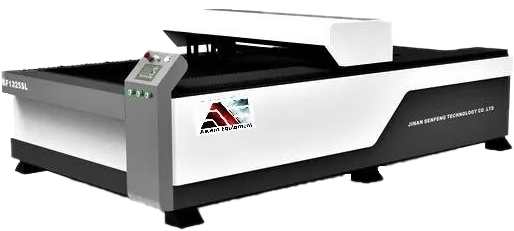

CO2 Laser Cutter

280W 4’x8’, 5'x10', and 6'x14'

Accurate screw drive and servo system

For nonmetal materials such as acrylic.

CO2+ Fiber Laser Cutter

150W CO2 for nonmetal and 1500W fiber for metal.

4'x8' accurate screw drive and servo system.

Heavy-duty design and high-quality components.

Working area sizes: 4’x8’, 5’x10’ or custom size With or without an automatic tool changer (ATC) and CCD camera.

Direct Servo motor and Helical drive system.

Instant Bubble Roll Machine

Simple, easy-to-use operation

Save valuable warehouse space.

Small footprint

Stand and roll Winder

The rolls are a lot cheaper than purchasing premade

bubble wraps

Let Ascent Experts Assemble All the Pieces of The Equipment Puzzle for your Company

Contact info

Direct line: 416-953-8104

Toll-free: 1-800-927-5107 Extension 1008

Tel: 647-494-7800 Extension 1008

Para asistencia en español marque Ext. 1006.

dov@ascentge.com

Buffalo, New York and Toronto, Ontario

All Rights Reserved | Ascent Equipment (USA) LLC

* Ascent reserves the right to change specifications without notice

All Rights Reserved | Ascent Equipment (Canada) Inc.

Smart Site Design & SEO Services by Green Lotus Agency