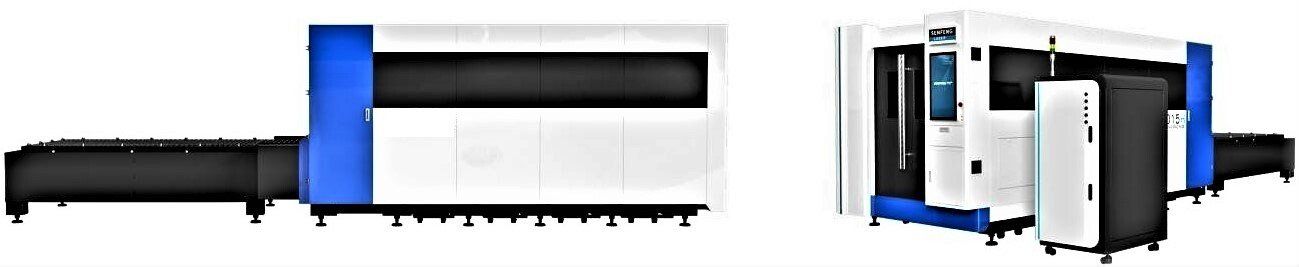

CNC FIBER LASER CUTTER 5’X10’

Performance:

- Recommended for the sign industry 3000W or 4000W

- High-speed and accuracy

- Shuttle table for loading and unloading

- Fully enclosed working area FDA certified

- Aluminum cutting with assist of dry compressed air rather than nitrogen

- Include all the components: laser source, water cooling, dust/fume collector, regulator, and UL/CSA transformer

- Control software

- Installation, training, and support from US-based factory technicians

Price:

- Include two years comprehensive warranty

- Shipping, installation, and training at your place by certified factory North American technicians

- One year consumable parts

- Optional air compressor

Cutting Materials

Carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized steel, silicon steel sheet, electrolytic sheet, titanium alloy, manganese alloy, etc.

Aluminum cutting with dry clean compressed air

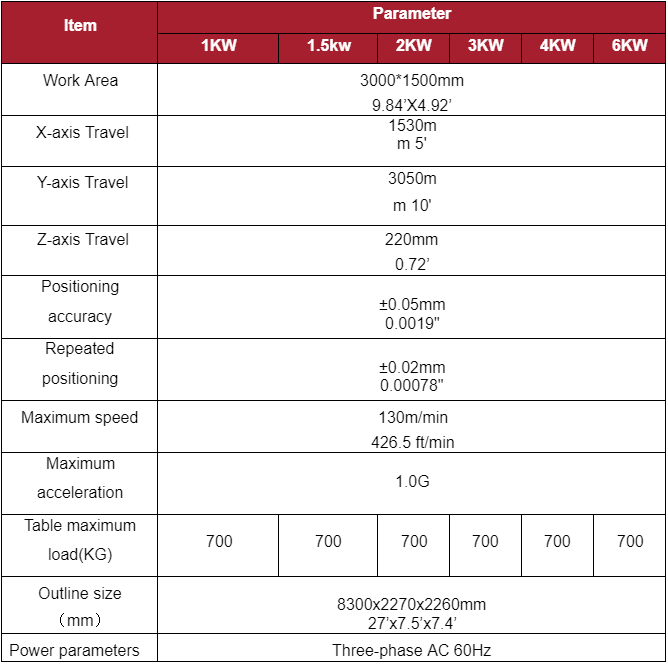

Cutting Parameters:

Stainless steel: 0.040” Thickness cutting speed 131”/min

Carbon steel: 0.5” Thickness cutting speed 5.5”/min

Brass: 0.040”” Thickness cutting speed 115”/min

Aluminum: 0.040”” Thickness cutting speed 2”/min

Aluminum: 0.5” Thickness cutting speed 1.3”/min

Cutting Thickness from 0.016” up to:

| Material | 1000w | 1500w | 2000w | 3000w | 4000w | 6000w |

|---|---|---|---|---|---|---|

| Carbon steel | 0.5” | 0.62” | 0.7” | 0.8” | 1.0” | 1.0” |

| Stainless steel | 0.2” | 0.23” | 0.3” | 0.5” | 0.5” | 0.5” |

| Brass | 0.11” | 0.2” | 0.23” | 0.3” | 0.3” | 0.3” |

| Aluminum | 0.11” | 0.23” | 0.3” | 0.4” | 0.5” | 0.5” |

Highlight features:

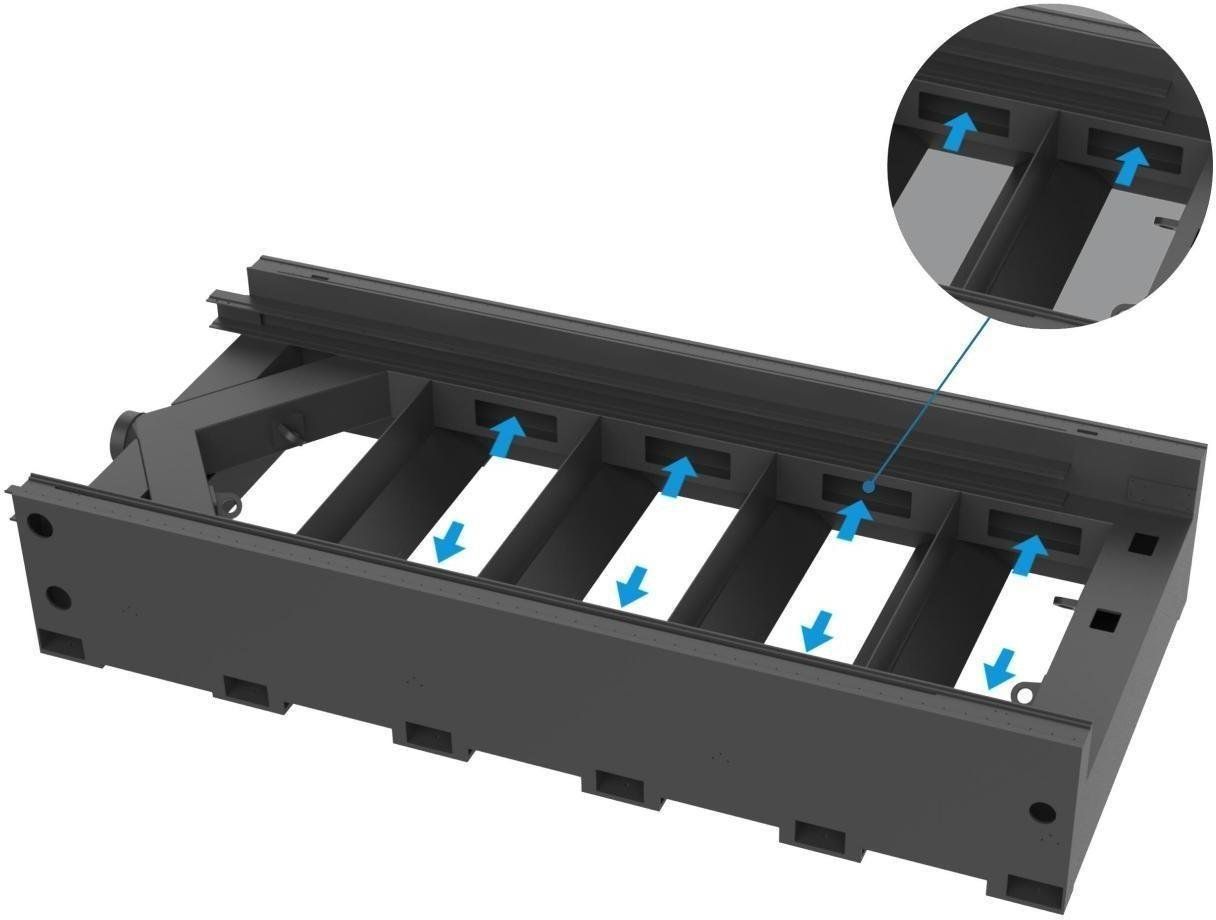

Intelligent surrounding cyclone negative pressure dust removal

Intelligent surrounding negative pressure partition dust removal system, according to the current cutting position, intelligently switch the air outlet, time-sharing, partition, and sectional air exhaust, together with the back-shaped sealing structure design at the bottom of the base to realize smokeless cutting.

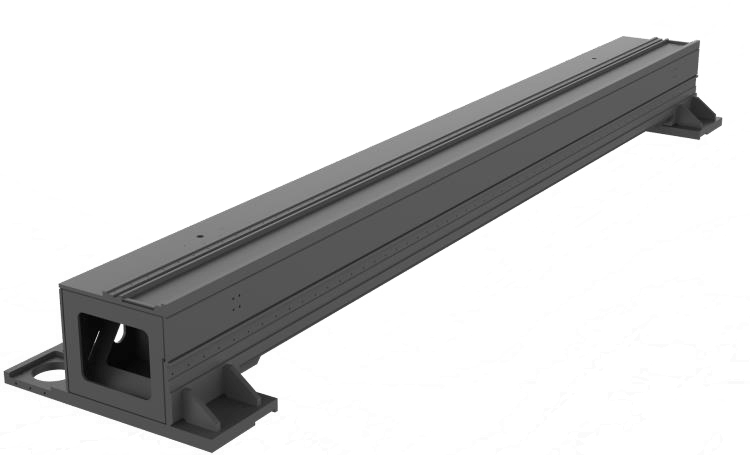

Strong Aviation Aluminum Beam

Aviation-grade high-strength aluminum alloy beams, lightweight, built-in triangular reinforced structure, strong rigidity, good shock absorption;

Two-stage machining rough machining eliminates internal stress and fine machining after secondary vibration aging treatment to ensure the beam’s overall strength and stability.

Automatic gas distribution device for auxiliary gas

The CNC laser cutting machine can control the oxygen automatically and control its flow and pressure independently. The equipment software is configured to select the auxiliary gas function automatically.

The type and pressure of the auxiliary gas can be automatically set and chosen through the numerical control program without manual operation. The pressure of compressed air and oxygen can be adjusted between 2.17 to 87 PSI, and the pressure of nitrogen can be adjusted between 2.17 to 362 PSI.

In addition, the actual air pressure at the exit of the cutting head can also be easily read and displayed on the panel in real-time.

More Details:

Automatic Focusing Fiber Laser Cutting Head

- The laser head has a substantial advantage on medium power large format fiber laser cutting application.

- A completely sealed internal structure of the laser head can avoid the optical part polluted by dust.

- Two-point centering adjustment of laser head; the focus adjusting uses imported motor driving and has excellent improvement in perforation.

- The protective lens uses a convenient replacement drawer.

FSCUT2000 Software

Convenient installation, easy debugging, excellent performance, complete solutions, stable and reliable, easy deployment, easy debugging, safe production, rich functions, superior performance, etc.; support and provide modular, personalized, automated, and information solutions that can be realized Memory cache, robust cutting process database, various of cutting parameters of different thicknesses and different plates, fast operation and efficient cutting.

- We reserve the right to change specifications without notice

Let Ascent Experts Assemble All the Pieces of The Equipment Puzzle for your Company

Contact info

Direct line: 416-953-8104

Toll-free: 1-800-927-5107 Extension 1008

Tel: 647-494-7800 Extension 1008

Para asistencia en español marque Ext. 1006.

dov@ascentge.com

Buffalo, New York and Toronto, Ontario

All Rights Reserved | Ascent Equipment (USA) LLC

* Ascent reserves the right to change specifications without notice

All Rights Reserved | Ascent Equipment (Canada) Inc.

Smart Site Design & SEO Services by Green Lotus Agency