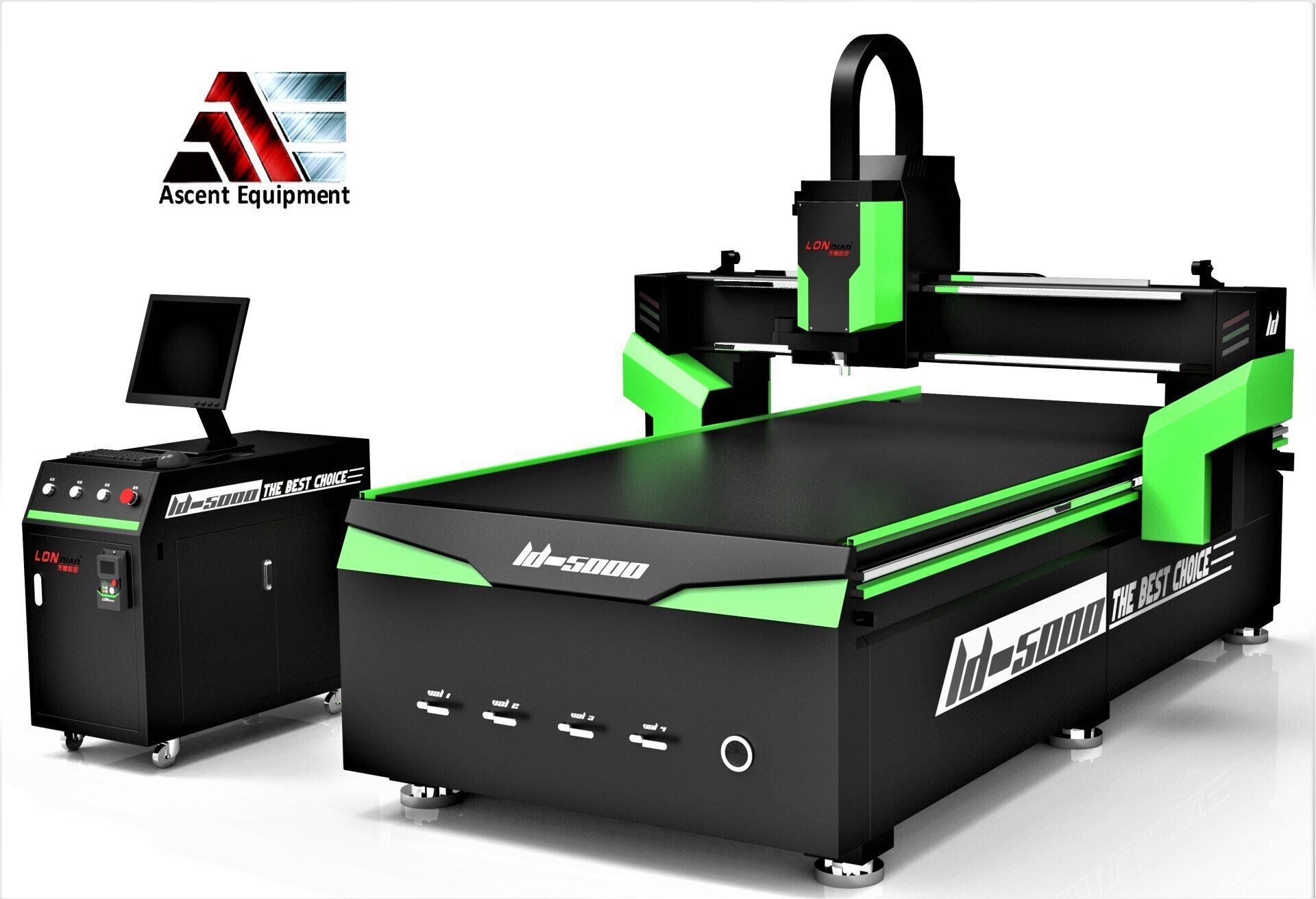

CNC ROUTERS

High-quality CNC routers are designed to work with different materials state-of-the-art technology for processing acrylic, PVC, aluminum, polycarbonate, and other materials.

- Heavy-duty design and high-quality components

- Working area sizes: 4’x8’, 5’x10’ or custom size

- With or without automatic tool changer (ATC) and CCD camera

- Direct Servo motor and Helical drive system

LD-5000S ATC: Automatic Tool Change

- Drive motor: YASKAWA servo motors & drivers 1.3KW on X, Y-axis, and 850W on Z-axis

- Japanese SHIMPO reducers on X and Y-axis

- Control system: Taiwan SYNTEC 6MD control system & MPG

- Table: vacuum table with T-slots

- X Y Z transmission: Germany WMH helical rack drive on X and Y axis, Taiwan TBI ball screw transmission on Z-axis

- Spindle power: Italy 9.5KW HITECO air cooling spindle (ATC)

- Spindle speed: 0-24000 rpm/min

- ISO30 tool holder 4 pcs

- Vacuum hose and dust brush on Z-axis

- Vacuum pump: 4KW German BECKER vacuum pump

- Quantity of tool magazine: 4 to 8 pcs (linear type)

- Independent control cabinet

- Guide rails: Japanese THK linear guide rails

- Popup Locating Pins 2 pcs along X-axis and three pcs along Y-axis

- Inverter: 11kw Italy INOVANCE

- Power: 380V/60Hz/3PH

- AC contactor: France Schneider electric components

- Automatic tool sensor

- Automatic lubrication system

- Auto mist cooling system

- Machine head pass aluminum oxidation treatment

- Machine body pass heat treatment

- Dust/debris collector (2 bags)

LD-5800-A CCD & Knife CNC router machine

Print Finishing with Knife:

An oscillating knife option is an essential tool for businesses that need to process flexible materials, including packaging foam, foam core, gator foam, corrugated plastic, or cardboard. These materials all present challenges for the traditional router or knife tools, but the ‘sawing action’ of the oscillating knife allows it to slice through these materials efficiently, delivering clean cut edges without fraying.

The oscillating knife option can cut a range of materials; here are a few that spring to mind:

- Medium-density foam

- Rubber

- Card

- Fabrics/textiles

- Cortex

- Fiberboard

Recommending G code post-processor

VCARVE PRO

A powerful yet incredibly easy-to-use design. It contains all the tools you need for 2D machining as well as high-end V-Carving features. Design and layout tools include true shape nesting, single line fonts for engraving, curve and arc fitting, and many more. NC programs produced by VCARVE PRO support ATC and can include advanced features such as tabs, ramping, pocketing, lead-in/out, and auto inlays.

Let Ascent Experts Assemble All the Pieces of The Equipment Puzzle for your Company

Contact info

Direct line: 416-953-8104

Toll-free: 1-800-927-5107 Extension 1008

Tel: 647-494-7800 Extension 1008

Para asistencia en español marque Ext. 1006.

dov@ascentge.com

Buffalo, New York and Toronto, Ontario

All Rights Reserved | Ascent Equipment (USA) LLC

* Ascent reserves the right to change specifications without notice

All Rights Reserved | Ascent Equipment (Canada) Inc.

Smart Site Design & SEO Services by Green Lotus Agency