ASCENT Channel Letters CNC Bending Machines

We may not be the only channel letter bending machines company in North America, but we have certainly raised the bar.

CNC channel letter bending and trim equipment

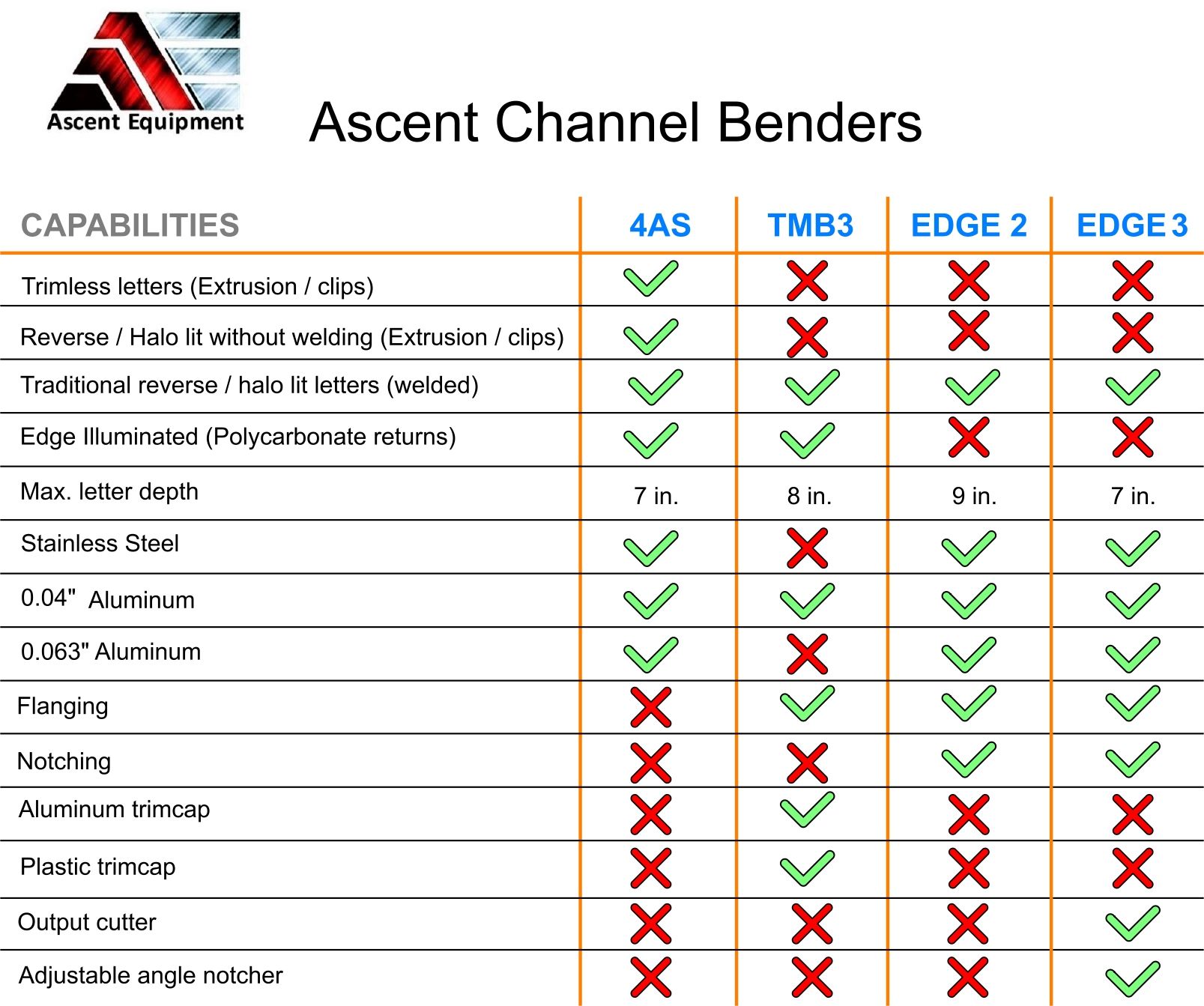

- Ascent 4as:

Compatibility: Supports nonproprietary UL Ascent extrusions, aluminum coils, and stainless steel

Features: Create channel letters without trim, reverse/halo without welding, illuminated plastic side return (an industry first) and stainless steel.

- EDGE2 Bending Machine:

Type: Traditional “notching and flanging” bending machine.

Accuracy: high accuracy

Pricing: Offers the most competitive price in North America.

- TMB3 Combination Bending and Trim Machine:

Features: The only machine to create trim from flat aluminum coils (industry first).

Functionality: Combines bending and trim functions in a single machine.

Material Compatibility: Capable of working with flat aluminum coils and plastic trims

There are two basic types of channel letters:

- Conventional channel letters that utilize trim or reverse/halo with welding using the machine Ascent-Edge or TMB3

- “New style” channel letters that do not require trim and reverse/halo without welding using the machine Ascent-4AS

Each of these styles consists of the following components; letter face (with or without trim), letter side returns, back and lighting source (LED). To automate channel letter returns, CNC bending machines are utilized. Traditional bending machines take flat aluminum coil and cut “notches” into the aluminum to create a flange. This allows for the bending of the aluminum into the shape of the letter, which is done either automatically or quite often manually.

We took the approach of developing our CNC Bending Machines to create channel letter returns from aluminum profiles (UL certified for indoor and outdoor) and using our unique pneumatic mailer gun; This system enables us to produce new-style channel letters that do not require trim. It also produces reverse/halo letters (that do not require welding) and our newest technology of utilizing liquid polyurethane/epoxy that replaces cut acrylic for the face.

Furthermore, our system utilizes stainless steel clips to connect the back of the letter to the side return.

The result is a cleaner letter that is easier and faster to produce with significantly reduced labor costs and easier installation.

With Ascent technology, we achieved price/performance; you can purchase the

Ascent-4AS + Ascent-Edge2

Or

Ascent-4AS+Ascent TMB-3 Trim machine

For the almost same price as one machine from the competition!

The price including installation and training at your place

Over 40,000 bending machines are sold worldwide!

Fourth-generation Ascent bending machine process aluminum, stainless steel, galvanized steel, non-proprietary aluminum UL extrusion/profiles, and other “exotic” materials. The machine produced Letters without trim, Reverse/halo (without welding), Plastic side return, Epoxy letters, and other channel letters. There is not tools change over (all software-driven) comes completely calibrated.

We guarantee the industry’s simplest assembly process with the lowest labor costs and competitive prices on Ascent UL aluminum extrusions/profiles for side returns.

Bending machine to make “notching and flanging” trim cap and reverse/halo type channel letters from aluminum coils up to 0.063” and stainless steel.

A full-scale machine high output very accurate with a tight radius bending option and the most affordable price.

The machines have three functions:

- Making side return from 0.040” aluminum

- Converts flat aluminum into trim and then automatically forms the trim into the letter’s shape

- Process traditional plastic trims (3/4", 1" and 2")

Let Ascent Experts Assemble All the Pieces of The Equipment Puzzle for your Company

Contact info

Direct line: 416-953-8104

Toll-free: 1-800-927-5107 Extension 1008

Tel: 647-494-7800 Extension 1008

Para asistencia en español marque Ext. 1006.

dov@ascentge.com

Buffalo, New York and Toronto, Ontario

All Rights Reserved | Ascent Equipment (USA) LLC

* Ascent reserves the right to change specifications without notice

All Rights Reserved | Ascent Equipment (Canada) Inc.

Smart Site Design & SEO Services by Green Lotus Agency